Guide to Engaging China Injection Molding Suppliers

The important meeting has recently finished, your new project has the green light, the schedule is tight, and funding is, to put it mildly, limited. Then someone—maybe your boss, maybe the finance director—utters the phrase that sends a little jolt down every project manager’s spine: “We should look at sourcing this from China.”

You nod, of course. On paper, it’s logical. The cost savings can be huge. However, your brain is racing with concerns. You’ve heard all the horror stories, right? Quality failures, endless communication gaps, shipments arriving months late and nothing like the prototype. It feels like walking a thin line between big savings and total project failure.

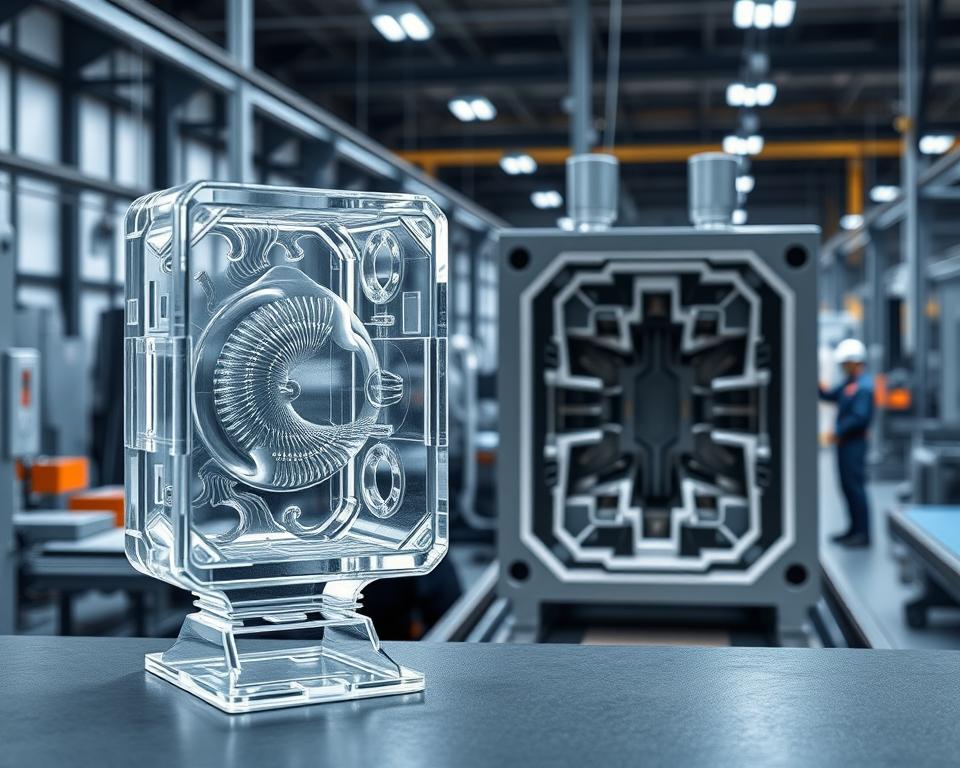

Here’s the thing, though. Sourcing plastic mold can be a calculated project. It’s simply another project with clear steps. And like any project, it succeeds or fails based on the process you follow. It’s less about finding the absolute cheapest quote and more about finding the right partner and managing the process with your eyes wide open. Ignore the nightmare anecdotes. Here’s a practical playbook to nail it.

First Things First: Your Homework

Before you mention “supplier” or browse Alibaba, organize your internal data. Truthfully, over fifty percent of offshore sourcing issues originate in an unclear project brief. You cannot expect overseas partners to interpret your unspoken requirements. A vague RFQ is like telling a contractor to bid on “a house.” You’ll get wildly varied quotes that are useless.

Your goal is to create a Request for Quotation, or RFQ, package that is so clear, so detailed, that it’s nearly impossible to misinterpret. This package is your project’s foundation.

What belongs in your RFQ?

Start with your 3D design files. They’re essential. Use standard formats such as STEP or IGS to ensure compatibility. This is the authoritative CAD geometry.

However, 3D alone won’t cut it. Include precise 2D engineering drawings. Here you specify what 3D can’t show. Examples include tolerances (e.g., ‘25.00±0.05 mm’), material grade, surface finish requirements, and functional callouts. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

Next up, material. Don’t label it simply “Plastic.” Nor just “ABS.” Get precise. If you need SABIC Cycolac MG38 in black, say exactly that. Why so detailed? Because there are thousands of plastic variations. Specifying the exact resin grade ensures you get the strength, flexibility, UV resistance, and color consistency you planned for with plastic mold injection.

They can offer alternatives, but you must provide the initial spec.

Don’t forget the commercial info. What is your Estimated Annual Usage (EAU)? They need clarity: is it 1,000 total shots or a million units per annum? The tool design, the number of cavities, and the price per part all hinge on this number.

The Great Supplier Hunt

Now that your RFQ is pristine. who gets your RFQ? The internet has made the world smaller, but it’s also made it a lot noisier. Locating vendors is easy; vetting them is the real challenge.

Begin on popular marketplaces such as Alibaba or Made-in-China. They offer breadth but not depth. Use them to build a shortlist, not the final list. You’ll want to quickly build a list of maybe 10 to 15 companies that look promising.

Still, you must dig deeper. Perhaps hire a local sourcing specialist. True, they charge a fee. But a reputable agent brings pre-screened factories. They handle local liaison and oversight. As a newcomer, this offers priceless security. Think of it as insurance for your project timeline.

Another classic method? Trade shows. If you have the travel budget, attending a major industry event like Chinaplas can be a game-changer. Nothing beats a face-to-face conversation. You can handle sample parts, meet the engineers, and get a gut feeling for a company in a way that emails just can’t match. Also, leverage the tried-and-true referral network. Ask other project managers in your network. A recommendation from a trusted peer is often worth its weight in gold.

Separating Real Suppliers from Pretenders

After firing off that RFQ to a broad pool, the quotes will start trickling in. Some will be shockingly low, others surprisingly high. Your task is to filter them down to 2–3 credible finalists.

How to proceed? It blends technical checks with intuition.

Begin with responsiveness. Do they respond quickly and clearly? Can they handle detailed English exchanges? The true litmus: are they raising smart queries? A great supplier will review your RFQ and come back with thoughts. “Have you considered adding a draft angle here to improve ejection?” or “We see your tolerance requirement here; our CMM can verify that, but it will add to the inspection time. Is that acceptable?” This is a massive green flag. It proves their expertise and involvement. A supplier who just says “No problem” to everything is a walking red flag.

Then confirm their machinery specs. Ask for a list of their equipment. Review examples of parts akin to your design. If you’re making a large, complex housing, you don’t want a shop that specializes in tiny gears.

Finally, inspect the factory. You can’t skip this. Just as you interview hires, audit suppliers. You can either go yourself or, more practically, hire a third-party auditing firm in China to do it for you. They perform a one-day factory inspection. They will verify the company is real, check their quality certifications like ISO 9001, assess the condition of their machinery, and get a general feel for the operation. That small investment can save you thousands.

From Digital File to Physical Part

After picking your vendor, you’ll agree on terms, typically 50% upfront for tooling and 50% upon first-sample approval. Then comes the real action.

Initially, expect a DFM report. DFM stands for Design for Manufacturability. It’s the engineering critique for moldability. The report calls out sink-risk zones, stress-causing corners, and draft angle gaps. A detailed DFM shows expertise. It becomes a joint effort. You work with their engineers to refine the design for optimal production.

When you greenlight the DFM, they machine the mold. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These are your initial mold shots. It’s your first real test.

Expect T1s to need tweaks. It’s par for the course. There will be tiny imperfections, a dimension that’s slightly out of spec, or a blemish on the surface. You critique, they refine, and T2 plastic mold company parts arrive. This process might take a couple of rounds. Build buffer time for sample iterations.

Finally, a flawless part arrives. It matches all specs, has a pristine finish, and works as required. This is your golden sample. You formally approve it, and this sample is now the standard against which all future mass-produced parts will be judged.

Crossing the Finish Line

Landing the golden sample is huge, yet the project continues. Now comes full-scale production. How can you keep part #10,000 matching your golden sample?

You need a clear Quality Control plan. Typically, this means a pre-shipment audit. Bring in an external QC firm. They’ll sample parts, check dimensions and finish versus your drawings and golden sample, and report. You receive a full report with images and measurements. Once you sign off, you greenlight shipping and the last payment. This step saves you from a container of rejects.

Lastly, plan logistics. Clarify your Incoterms. Is your price FOB (Free On Board), meaning the supplier’s responsibility ends when the goods are loaded onto the ship in China? Or EXW, shifting all transport to you? These choices hugely affect landed cost.

Sourcing from China is a marathon, not a sprint. It relies on partnership-building. View them as allies, not vendors. Open dialogue, trust, and rigorous procedure deliver results. Certainly, it’s complex. But with this framework, it’s one you can absolutely nail, delivering the cost savings everyone wants without sacrificing your sanity—or the quality of your product. You’ve got this.